Contact No

+91 22 40620000

ISOMIL

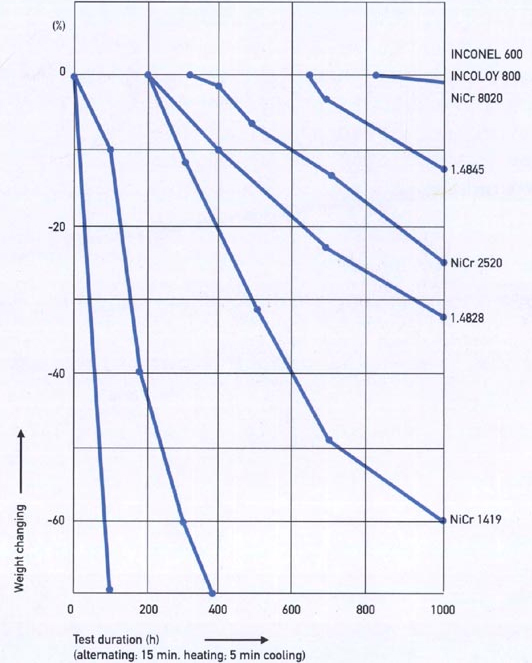

Scaling Resistance

Different sheath materials were heated in air in a cycle as follows: 15 min up to 980°C (indirect heating) , 5 mins cooling to room temperature, 15 min up to 980°C and so on.

The diagram below shows the loss in weight ( in% ) of the specimen versus the test duration (in hours) as a result of the flaking layers of oxide. It is clear that the scaling resistance of the alloys increases with the sum of nickel and chromium, at 980°C with temperature variation it is excellent in INCONEL 600 (2,4816) and still good 1.4841.On the other hand 18-9 steels are not suitable for application at this temperature.