Contact No

+91 22 40620000

HIGH TEMP. CABLE

HIGH TEMP. / SUPER TEMP. APPLICATIONS

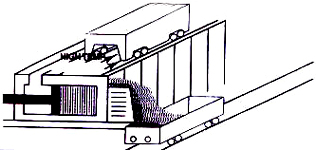

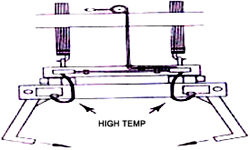

Coke Oven Charging Car

Discription / Operation

The coke oven charging car injects the coke into the furnace through the holes located on top of the furnace. HIGH TEMP. and RV 4.00 V03 cables supply power to the different charging car engines which are exposed to rising flames whilst charging. cable powers the sensors positioning the charging car.

Type Of Cables Used : High temperature

Lifetime : Five times the lifetime of the former cable used.

Constraints : Flame , Enviornment

Former Technology : Silicon cable, glass fibre braid

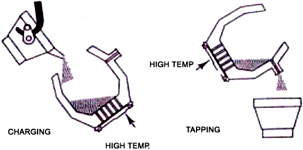

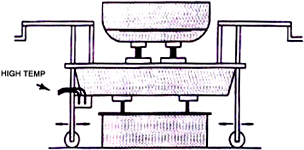

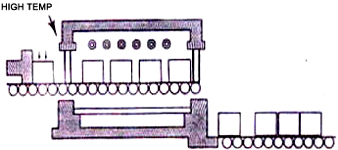

Converter

Discription / Operation

The converter tilts in two directions : - on one side to receive the hot metal, - on the other side to tap the iron into a teeming ladle (on a ladle car). The cable situated underneath the converter supplies power to the positioning sensors.

Type Of Cables Used : High temperature

Former Technology : Rubber cable with an asbestos tape.

Constraints : There is no major risk of thermal destruction. HIGH TEMP, is mainly used to guarantee lifetime and security of the equipment.

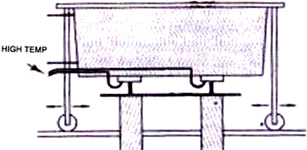

Teeming Ladel

Discription / Operation

The teeming ladle transports the molten steel from the converter to the revolving door near to the continuous casting. The cable supplies power the motor opening and closing the ladle gate which opens the way for the steel to the tundish.

Type Of Cables Used : High temperature

Former Technology : Thermal scattering through the ladle walls. , Molten steel spillage. ,

High ambiant, stifling temperature : between 300 and 400°C

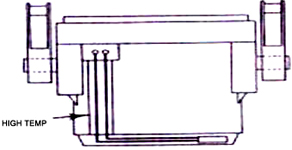

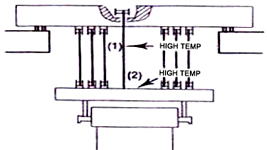

Overhead Crane - Ladel Transfer

Discription / Operation

The overhead crane transports a steel or cast iron ladle. Sensors transmit weight information box, and type (2) from the ladle to the transition box, and on cable (1) from the transition box to a measurement device situated on the winding torque motor. When emptying the ladle, flames are rising surrounding the compensator and burning the first meters of the winding cable.

Type Of Cables Used : High temperature

Lifetime : (1) = 3 TO 6 months

Former Technology : The lifetime of the former compensator cable type was 4 months.

Constraints : Rising of flames , Radiating heat on the compensator (2). , Flame, winding-up/unwinding.

Quantity : (2) = 55 m X 8 sensors

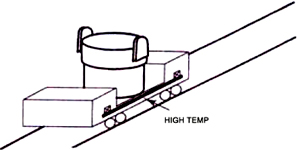

Ladel Car

Discription / Operation

The ladle car transports the molten steel from the electric furnace to the refining station. Here the steel will be transformed to different qyality types.

Type Of Cables Used : High temperature

Constraints : The channel in which the cable is installed is exposed to the molten steel when the ladle accidently overflows during transport. The cable supplies power to 4 weight sensors situated on each of the car wheels transmitting information on ladle weight and contents.

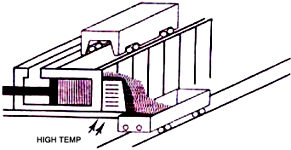

Coke Guide

Discription / Operation

The coke guide pushes the coke from the furnace to the ladle car. As the coke reaches temperatures of up to 1200°C, the use of high temperature cable is necessary. They supply power to the guide motors as well as to the lighting on top of the furnace doors where the radiating heat is very hight The sensors positioning the coke guide are powered by.

Type Of Cables Used : High temperature

Lifetime : Five times the lifetime of the former cable used.

Constraints : Flame, Environment.

Former Technology : Silicon cable, glass fibre braid.

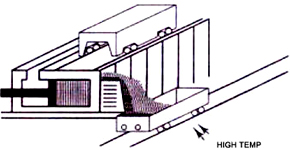

Ladel Car

Discription / Operation

The limit switches of the ladle car is powered by a HIGH TEMP cable 3 x 1,50 As the temperature is ambiant the use of HIGH TEMP type cable is not necessary Nevertheless, the radiating heat of the coke and to water spraying. For this application, proposed with PFA outer jacket (260°C continuous use).

Type Of Cables Used : High temperature

Lifetime : Five times the lifetime of the former cable used.

Constraints : Radiating heat, Moisture.

Former Technology : Silicon cable, glass fibre braid.

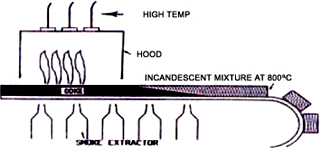

Hood or Burner

Discription / Operation

The burners ignite the coke to turn it into an incandescent mixture. The cable supplies power to the motorized valves which regulate the air/gaz output allowing the ignition of the burner.

Type Of Cables Used : High temperature

Lifetime : 1 week to 6 months

Constraints : The radiating heat reaches 800oC. Occasionally, flames are rising to the valves licking the cables during several minutes.

Former Technology : Cables with asbestos braid

Quantity : 50 m per burner

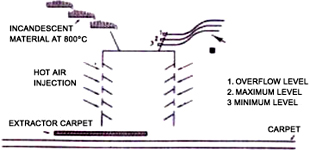

Level Control Flap

Discription / Operation

The conglomerate is poured into the cooling system through a hopper equipped with a flap detecting the minimum, maximum and overflow level. Hot air (200°C) cools down the conglomerate. Near to the flap, the radiating heat of the 800°C incandescent material reaches between 400 and 600°C. The cables situated near to the flap are exposed to theses temperatures on an estimated length of 5 m.

Type Of Cables Used : High temperature

Lifetime : As an extra length of cable is installed during the first wiring, the end of the cable, most exposed to the heat, can be replaced before the total length must be changed normally after one year.

Constraints : Radiating heat (800°C).

Former Technology : Cable with asbestos braid. At high temperatures this braid was cracking and the heat resistance was less efficient.

Quantity : 20 to 25 m per flap.

Tundish

Discription / Operation

Here the HIGH TEMP. cable is used for supplying power to the motor which operates the tundish valves, allowing the steel to pass from the tundish into the moulds. HIGH TEMP, cables are also used to power the tundish level controls.

Type Of Cables Used : High temperature

Constraints : The cables are exposed to the radiating heat of the steel as well as to steel projections. It is most important to have a reliable electrical system and to be able to close the valves immediately in the case of a malfunction.

Former Technology : Cable with asbestos briad.

Tundish

Discription / Operation

HIGH TEMP. cables are also used to power the tundish car. This is the car which lines up the tundish between the ladle and the moulds.

Type Of Cables Used : High temperature

Constraints : The cable is exposed to steel spillage and projections.

Former Technology : Cable with asbestos braid

Ingot Overhead - Crane

Discription / Operation

This crane takes ingots from the ingot moulding to the heater. The motors are powered by V 35 and V 4,00 wires, the control is carried out by V 2,50 wires.

Type Of Cables Used : Hybrid high temperature cable.

Lifetime : 1 week to 6 months

Constraints : High level radiating heat from the ingots.

Former Technology : Rubber cable

Quantity : 8 m.

Ingot Overhead - Crane

Discription / Operation

The blooms leaving the casting line are re-heted before being rolled. HIGH TEMP. cable supply power to the engines opening and closing the heater doors.

Type Of Cables Used : Multiconductor RV - high temperature cable.

Lifetime : The cable has never been changed after several years of use.

Constraints : The cable is exposed to radiating heat only during the opening of the furnace. The temperature rises to 200°C. HIGH TEMP, cables have been chosen as a safety measure to assure a good cable lifetime / to avoid any maintenance of the equipment.

Former Technology : Silicon cable.